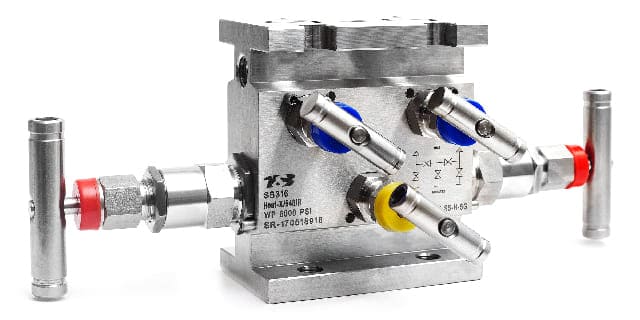

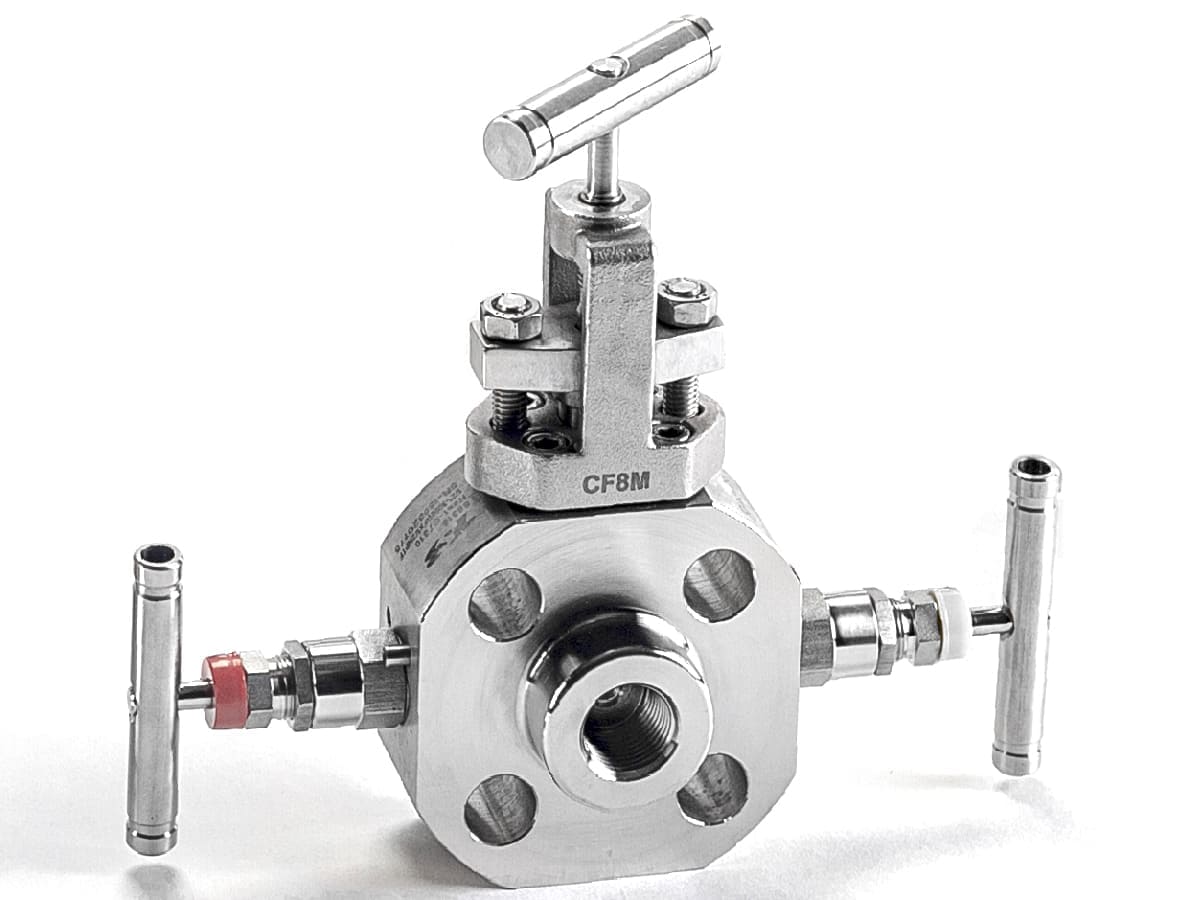

MONOFLANGE VALVES

-

Compact Design Needle Type Configuration

-

Fire Safe as per API 6FA

-

Metal Valve Seat with leak tested tightness as per BS6755 / ISO 5208 leakage rate A.

Valve Body Construction

- Single Piece Design

End Connection Variants

- Flange x Flange, Flange x Threaded

- Flange Variants – RF and RTJ

Valve Type

- OS & Y, Screwed, Anti-Temper Bonnet Assembly

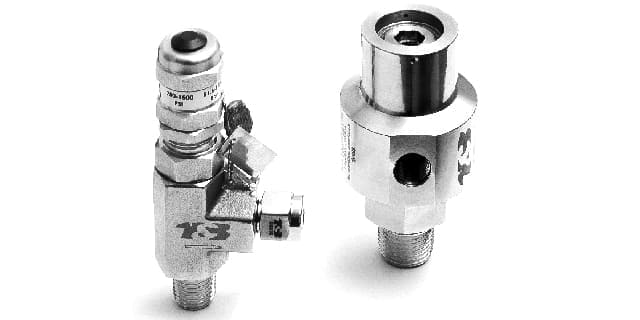

EndConnections

- NPT, BSPT and Flanged as Standard

Size range

- 1/2” to 2” and 12mm to 50mm

- Flange End and Male/Female Threaded Pipe End Connections

Operating Pressure Range

- Class150 toClass 2500

Gland Seal Materials

- PTFE, RPTFE as Standard for Bleed Needle Valve and Ball Valve Stem

- Graphite on request in High Temperature Applications

Needle Valve Seat Materials

- PTFE as Standard up to 200oC

- Graphite for temperatures up to 640oC

Design Standards

- Shell Design – In Accordance with ASME B16.34

- Flange – In Accordance with ASME B16.5(RF/RTJ)

Note: – As a drive for continuous improvements of our products, Powerlok reserves the right to change the descriptions contained in this brochure without prior notice. Consult local Agent or Factory for revisions and/or service related issues.