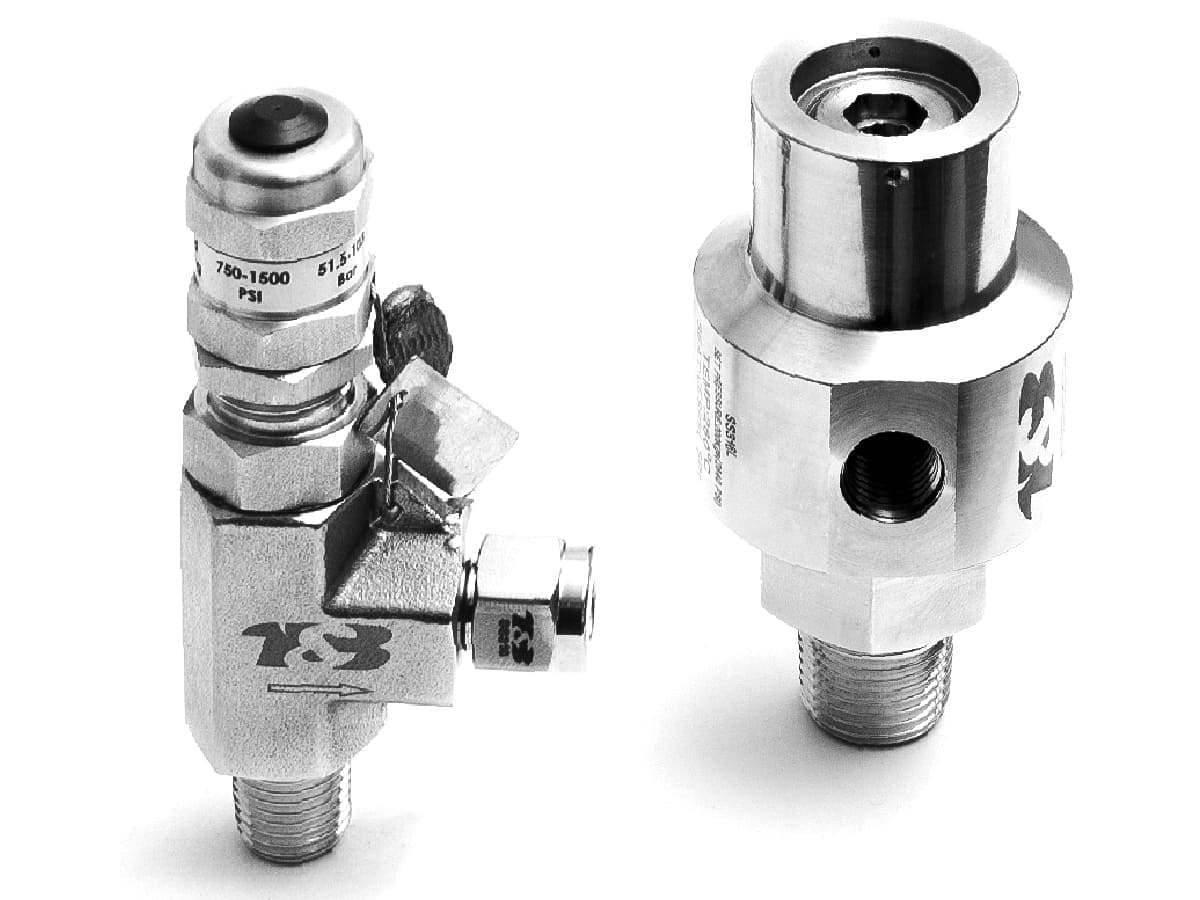

SAFETY RELIEF VALVES

-

Wide range of applications in all types of fluids

-

Relief Spring Sets of 10 psig to 6000 psig

-

External Set Pressure Adjustments

-

Factory Tested Set and Reseal performance

-

O-Ring Seat ensure bubble tight Shut off

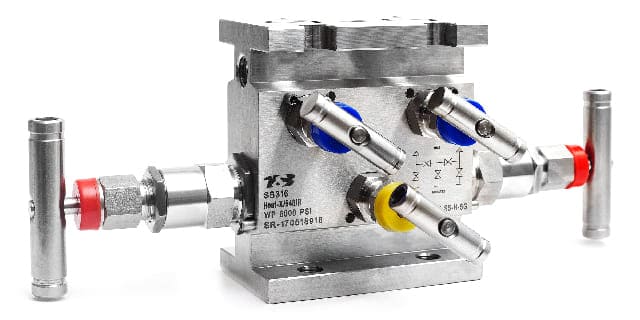

End Connections

- Powerlok™ Tube End, NPT, BSPT, BSPP, ISO, DIN and JIS pipe Threads

Size range

- 1/8” to 1” and 3mm to 25mm Tube End and Male/Female Threaded Pipe End Connections

Operating Pressure

- Up to 60000 psig

Pressure Relief Setting

- 10 psig to 6000 psig

Flow Rate

- 33.3 to 78 L/min.

Relevant Design Standards

– ANSI

- B31.1 Power Piping

- B31.3 Chemical Plant and Petroleum Refinery Piping

- B31.4 Liquid Petroleum Transportation Piping Systems

- B95.1 Terminology for Pressure Relief Devices

- ANSI/ASME PTC 25.3 Performance Test Code, Safety and Relief Valves

– API

- API RP 510 Pressure Vessel Inspection Code

- API RP 520 Recommended Practice for the Design Installation of Pressure

- Relieving Systems in Refineries: Part 1 Design; Part II – Installation

- API RP 521 Guide for Pressure Relief and Depressuring Systems

- API Standard 527 Commercial Seat Tightness of Safety Relief Valves with Metal to Metal Seats

- API Standard 2000 Venting

- Atmospheric and Low Pressure Storage Tanks

- API Guide for Inspection of Refinery Equipment Chapter XVI – Pressure Relieving Devices

– ASTM

- Boiler and Pressure Vessel Code

- Section VIII – Pressure Vessels

– NACE

- MR0175

-

Oil & Gas

-

Chemical & Petrochemical

-

Power Generation

-

Process Analytical

Note: – As a drive for continuous improvements of our products, Powerlok reserves the right to change the descriptions contained in this brochure without prior notice. Consult local Agent or Factory for revisions and/or service related issues.